3DGence CONNECT™

Engineered to meet the Industry 4.0 requirements, CONNECT™ links together the 3DGence ecosystem of hardware, software and materials to deliver end-to-end traceability of the additive manufacturing process.

Engineered to meet the Industry 4.0 requirements, CONNECT™ links together the 3DGence ecosystem of hardware, software and materials to deliver end-to-end traceability of the additive manufacturing process.

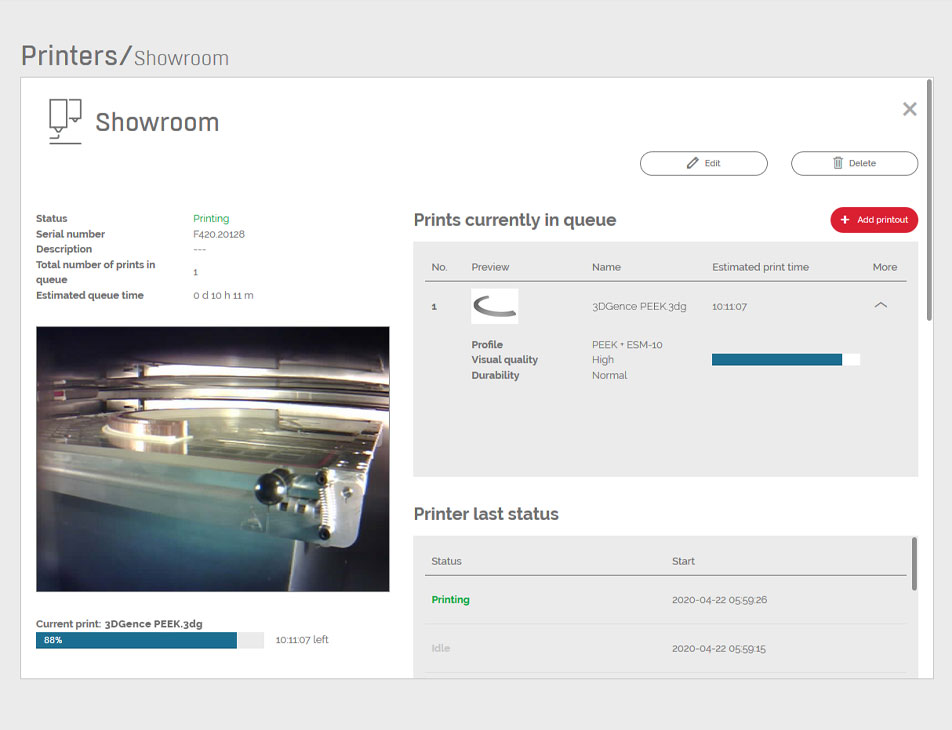

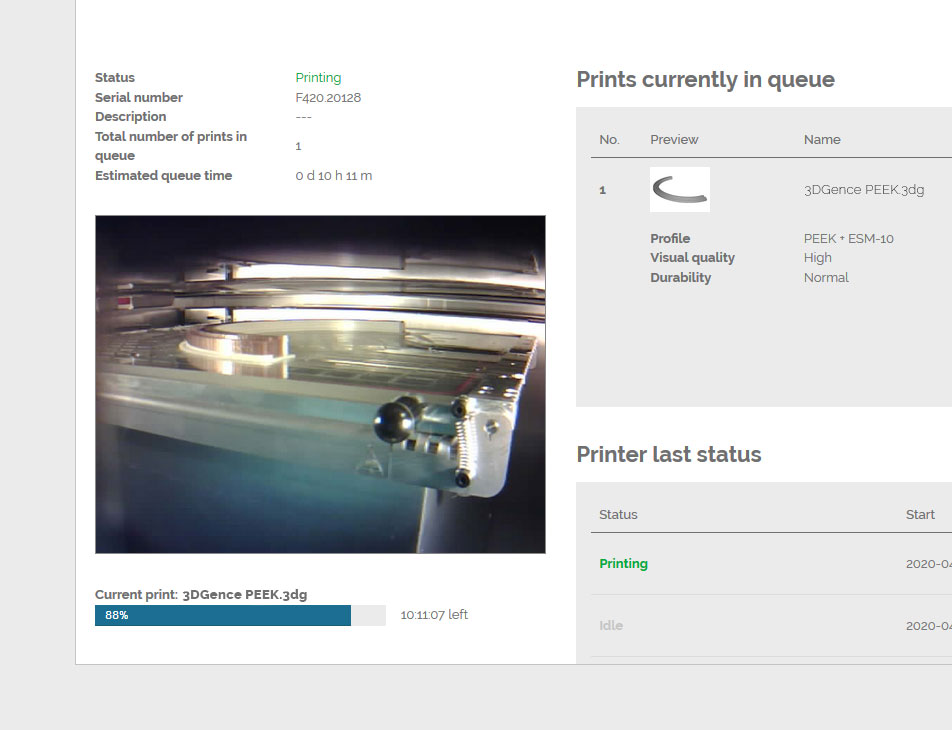

The user can start, cancel or queue the prints. The customer gets the full control of the process and job order, even on multiple printers, as well as real-time monitoring of the machine and print status.

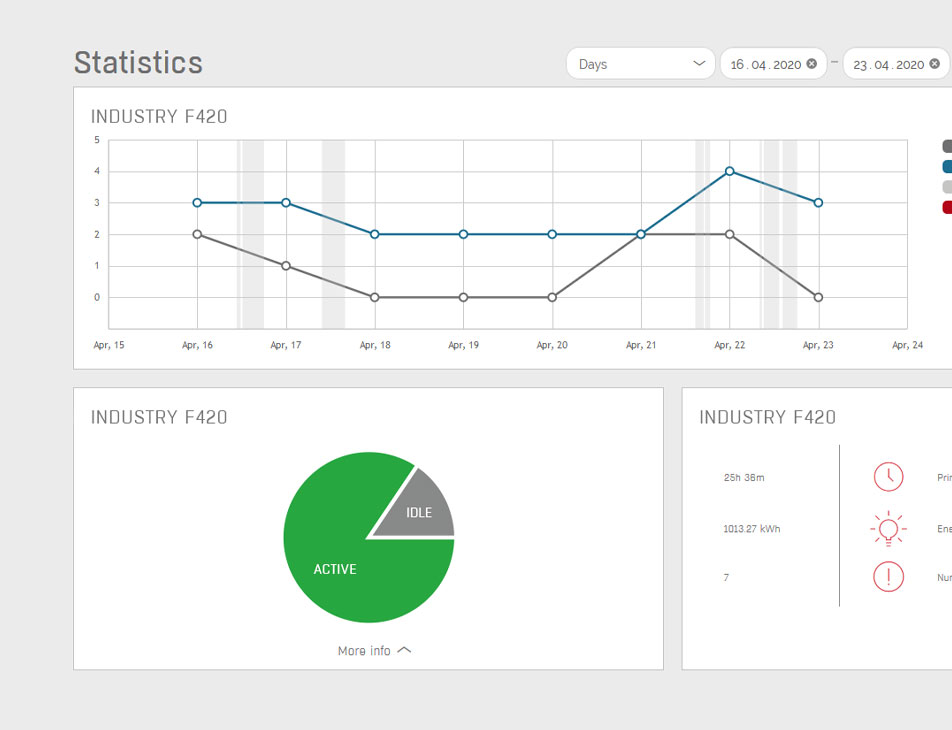

The software is able to aggregate and present the machine and material usage statistics. All the user data transferred via Cloud are safe thanks to asymmetric encryption.

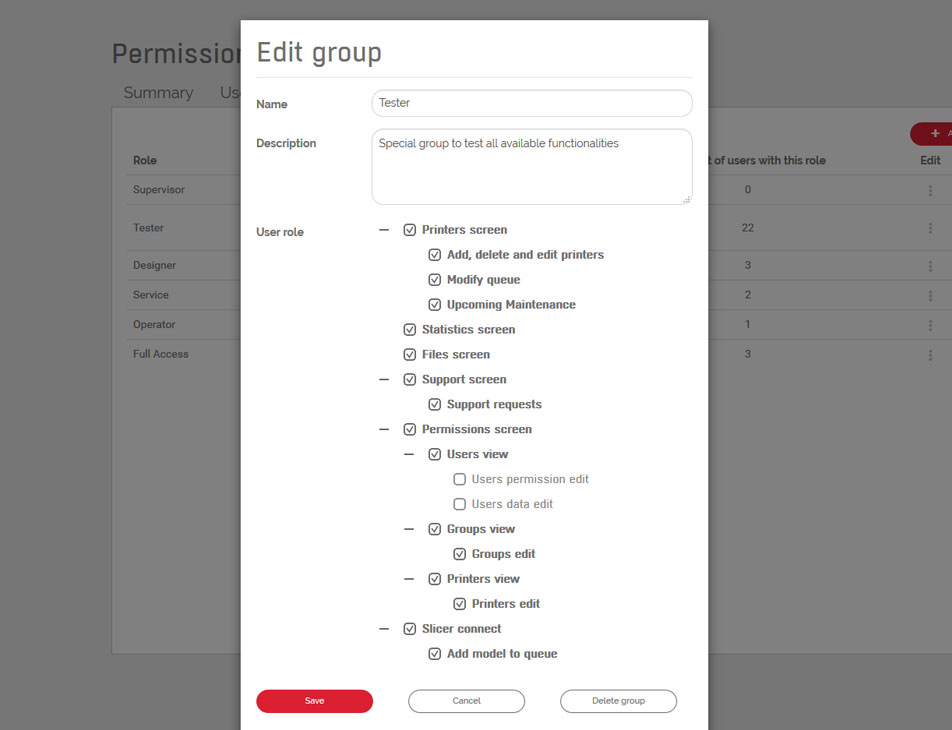

The access for the particular options in the Cloud can be restricted to predefined user groups. The administrator can differentiate the user groups in order to keep the process and all jobs safe.

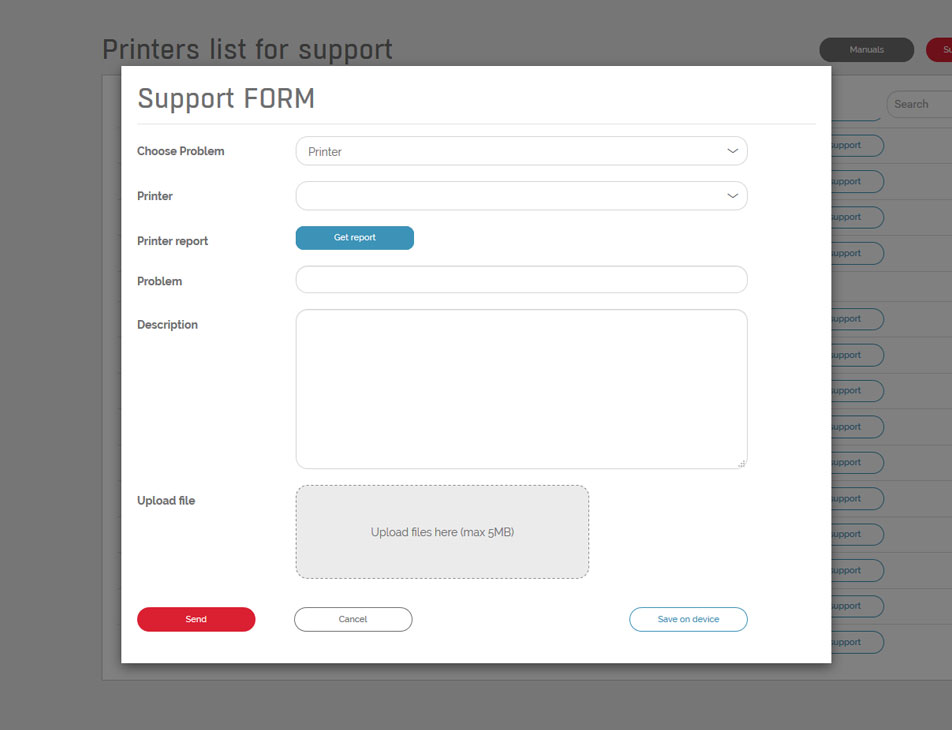

3DGence support team may use the Cloud software to access, diagnose and provide help remotely.

Possibility to get the preview of what has been printed, without the need of approaching the printer.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Cookies that are used to recognise you and remember your preferences or settings when you return to our site, so that we can provide you with a more personalised experience.

Cookies which measure how often you visit our sites and how you use them. We use this information to get a better sense of how our users engage with our journalism and to improve our sites and apps, so that users have a better experience.

Cookies that are used to collect information about your visit to our site, the content you have viewed, the links you have followed and information about your browser, device and your IP address.